Worldwide

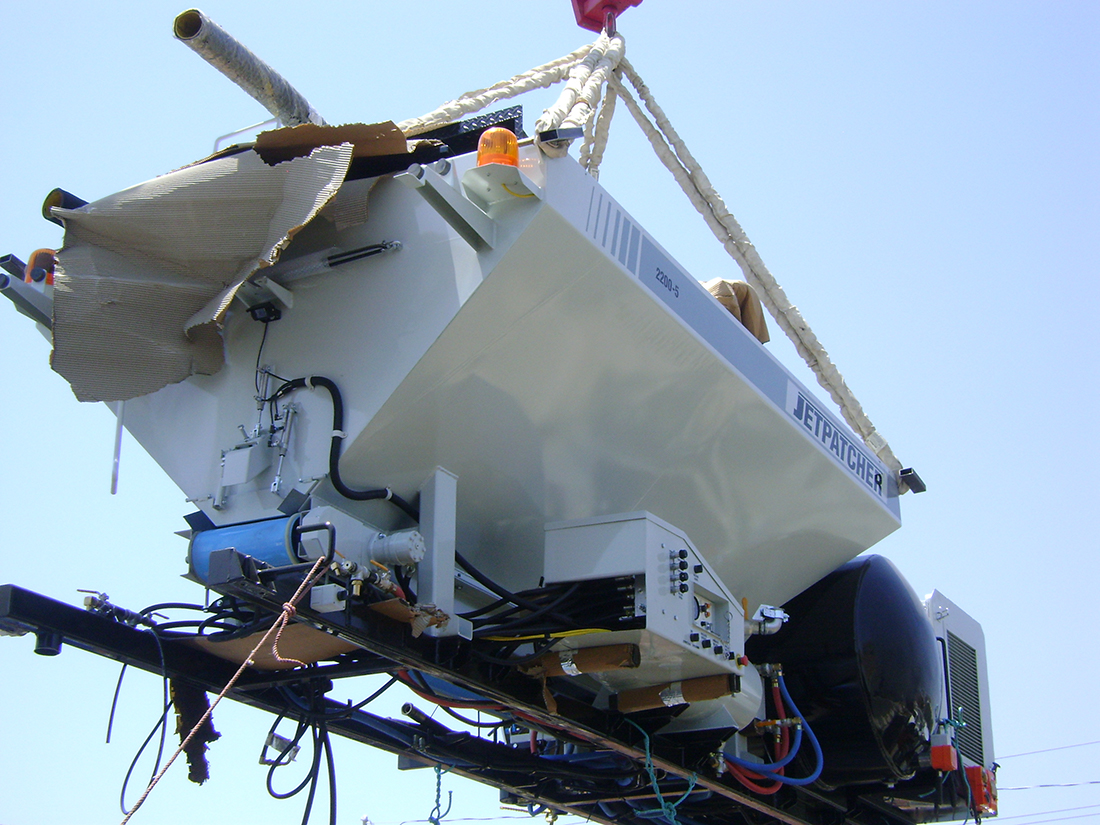

Our bespoke export units contain everything you need to perform Jetpatcher spray injection repairs wherever you are.

The equipment is supplied partially assembled, ready to install to your truck cab or chassis.

We can provide, or arrange for, an approved installer to be present to supervise installation and provide operator training. Costs on application.

We provide a technical advisory supervisor for materials and methods. A full 12 month warranty is provided on equipment (fair wear and tear excepted). The company maintains a full inventory of spare parts.

Why choose Jetpatcher?

Jetpatcher is the original patching machine, developed in 1987, and with over 900 units sold and operated in more than 40 countries around the world it is a proven system. Jetpatcher Corporation and their machinery are now established as the global market leader within the industry, with the most reliable machines and cost effective maintenance. Due to the speed and versatility of the machinery the process has proved a cost effective solution in every environment, meaning local authorities and municipalities have increased the number of repairs they can carry out using limited budgets. It takes approximately 2 minutes to fix the average size pothole using Jetpatcher, traffic can drive over the repair straight away and the repair is guaranteed to last a minimum of 12 months.

PURCHASING PROCESS

We have an experienced and knowledgeable sales & support team who will work with you to make your purchase as hassle-free as possible.

1. We will provide you with information about the various models so you can learn about Jetpatcher. This will include online seminars to explain the different machines and options available to the customer.

2. Once you have gained further knowledge about the Jetpatcher product we will discuss and study your situation, and how you wish to use the Jetpatcher, to advise the right series and options in order to get the job done in the quickest, best and most economical way.

3. Jetpatcher should be mounted on a truck or suitable trailer. In the case of a truck-mounted unit you can either send a truck chassis to the UK or we purchase one to your requirements and mount the system directly to it. However if you wish to purchase the chassis locally then one of our trained technicians will travel to your destination and commission the unit. In the case of a trailer-mounted unit we will custom build a heavy duty trailer in our Rugby factory and mount the Jetpatcher onto it or design the system to mount to your specific trailer.

4. After the quotation is reviewed and agreed upon an order will be placed for your machine and your product will be assembled and shipped to your location along with the spare parts and a commissioning engineer who will teach you how to use and maintain the Jetpatcher including suitability of materials etc.

5. We will stay by your side even after the purchase of a Jetpatcher in case you need any assistance, servicing or spare parts.

Export Process

All our machines are made here in our manufacturing hub in Rugby, UK. After rigorous testing, the bespoke Jetpatching machines are carefully loaded into containers for shipment and further delivery to your door. We’ll be on hand throughout to make sure everything goes to plan.